Industrial Rigging

Machine and equipment rigging company

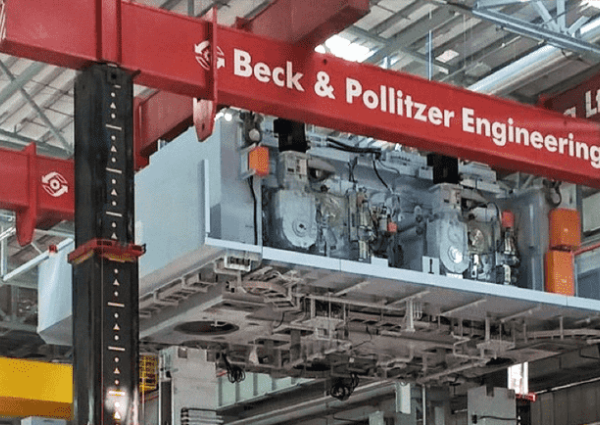

When it comes to the intricate world of industrial operations, one cannot underestimate the crucial role that equipment and machine rigging play. In today’s dynamic business landscape, companies across diverse sectors are faced with the ever-increasing challenge of efficiently relocating or installing heavy machinery and equipment. This is where the expertise of Beck & Pollitzer as reliable equipment and machine rigging company comes into play.

With precision, knowledge, and an unwavering commitment to safety, we ensure the seamless handling, transportation, and installation of machinery as part of our machine rigging services, empowering companies to optimize productivity, reduce downtime, and enhance operational efficiency.

Our rigging services: Seamless handling of your Industrial Equipment

Machinery rigging services are crucial for a multitude of reasons. Primarily, the safe and efficient handling of heavy machinery and equipment necessitates specialized equipment and techniques that surpass the capabilities of an average person or company. Engaging in the movement of machinery without the appropriate training and equipment can lead to severe injuries, substantial damage to the equipment itself, or even property damage. Read more about riggers, type of rigging equipment and rigging safety here.At Beck & Pollitzer, we possess the expertise, experience and trained staff required to execute intricate rigging tasks with the highest levels of safety and efficiency. Our services are delivered by expert engineering support teams comprised of Project Managers, Supervisors, Millwrights, Riggers, Mechanical Fitters, Electricians, Pipefitters, and Welders, which can also help with machinery move and factory relocation services.

Machinery rigging solutions: From dismantling to reassembling and reconnection

We take pride in our comprehensive turn-key services that cover every aspect of machine rigging. Our capabilities extend beyond the mere transportation of heavy machinery and equipment. With our expertise, we offer a complete solution that encompasses disconnecting and dismantling equipment, preparing your equipment for transport, loading, transportation, unloading, and reassembly, including mechanical and electrical connections.Beck & Pollitzer has the right equipment to suit any heavy and industrial rigging requirements. We have a 120,000-pound forklift, a 600-ton track-mounted gantry lifting systems, air dollies, mobile cranes, lifting accessories, and top-of-the-line optical and laser aligning equipment. When it comes to precision millwright and optical alignment included in our machine moving and rigging service, we can measure your machinery within a tolerance of .001 inches.

Expert rigging services: Tailored solutions for diverse industrial needs

At Beck & Pollitzer, we have a proven track record of excellence in providing machine removal and installation services across various industries. Our expertise extends to a diverse range of sectors, including pharmaceutical and chemical, auto stores and automated warehouses, automotive, and electric vehicle production, steel and aluminium industries, fast-moving consumer goods, plastics, building supplies, paper processing, canning, food and beverage, aerospace, battery electrification, warehouse automation, power generation, and other general manufacturing sectors.We take pride in offering our outsourced engineering services to numerous blue-chip manufacturing companies operating within these industrial production sectors. Our 160 years of experience in the sector, enable us to deliver successful rigging services tailored to the specific requirements of each industry.

We offer professional rigging and lifting services for a wide range of heavy machinery, including but not limited to the following examples:

- Extrusion presses, Stretchers, Coilers, Roll-formers, Ovens

- Stamping presses, Mold machines, Water Jet machines

- Injection Molding machines

- CNCs, Lathes, Press brakes

Equipment rigging services: Safeguarding your investments with expert handling

At Beck & Pollitzer, our machine rigging projects benefit from our exceptional project management skills. As both project manager and main contractor, we ensure smooth operations for projects of any size. With a dedicated team of project management experts under our control, sometimes supplemented by specialist subcontractors, we maintain a consistent and coordinated approach.Drawing from our extensive experience in thousands of projects, we develop realistic work programs in collaboration with our clients’ project teams, ensuring successful outcomes. Our commitment to innovation includes comprehensive project control documentation, which helps track the progress of current projects and allows us to gather valuable insights. We prioritize health and safety management, adhering to regulations and procedures to maintain a secure working environment. Trust Beck & Pollitzer to handle your machine rigging projects with efficiency and expertise, delivering outstanding results.

International machinery rigging solutions

A machine rigging project can be intricate and demanding as the risks associated with delays or incorrect installations can lead to significant disruptions and potential financial losses for clients, highlighting the criticality of getting it right the first time.At Beck & Pollitzer, machine rigging is one of our core services, and we are well-equipped to assist with all your machinery rigging requirements, both domestically and globally. With a strong presence of over 30 offices across 17 countries, including Japan, Turkey, India, USA, and Australia, we possess a unique advantage of mobilising local teams on each side for most international relocations. Our extensive experience encompasses dismantling in one location and seamlessly transporting and installing machinery in another, ensuring a smooth transition throughout the entire process and is substantiated by our successful completion of numerous machine installation and relocation projects each year, earning us the trust and satisfaction of customers worldwide.

Health and safety is our priority

At Beck & Pollitzer, the safety of our workforce, as well as all individuals associated with our clients’ projects, are of paramount importance to us. We deeply embed health and safety principles into every aspect of our operations, including when it comes to rigging services.Our core philosophy revolves around the belief that all accidents can be prevented, irrespective of project location, scale, or complexity. Because we can complete your industrial or heavy rigging project around the world, we take great pride in aligning our entire business to adhere to a single global health and safety standard. We remain dedicated to staying up to date with safety regulations and implementing rigorous measures to avoid potential hazards and project mishaps.

Contact us

Given the unique nature of each project, we offer customized solutions that are specifically tailored to meet your individual requirements. For comprehensive guidance and assistance regarding your equipment and machine rigging requirements, please contact our local office where our team is ready to provide further advice and support.Great job by Beck & Pollitzer! The rigging work was completed in a professional manner, safely and within the expected timeframe. Hope to see the crew on our next project!

Our rigging services include:

- Rigging plan and risk assessments

- Project management to oversee the planning, coordination and execution of rigging projects

- Method statements, planning and communication of the work in advance

- Provision of insurance

- Liaison with local authorities

- Establishing clear communication channels between the various rigging team members and stakeholders

- Inspection of the rigging before final use

- Machinery and equipment crating

- Provision of accredited personnel to manage other lifting contractors

- Setup and dismantling of the rigging equipment

- Inspection of the loads for any defects or damages that may affect their stability during lifting

- Selection and preparation of the appropriate rigging equipment based on the load characteristics such as weight, shape and centre of gravity

- Safely moving heavy equipment through confined spaces

- Lifting, positioning and bolting components to build up the scaffolding

- Setting, aligning, and levelling heavy equipment machinery for optimal performance

- Compliance with state and company safety procedures

- Manipulation of the rigging lines to turn suspended loads

- Conducting post-rigging inspections

- Final documentation and reporting

Heavy rigging and internal relocation of a shear press

Our team of highly experienced riggers recently executed a demanding project involving the heavy rigging and internal relocation of a shear press in Greenville, SC. This project was carried out for a valued and repeat client, specializing in the manufacturing of warehouse racking systems.

The initial phase of this meticulous rigging and moving operation focused on the internal relocation of a 40,000-pound shear press, creating space for forthcoming equipment installations. Subsequently, we successfully offloaded and relocated a new 27-foot roller metal forming machine, weighing 28,000 pounds, to the designated area within the facility. To ensure utmost safety during the intricate process, our team utilized a 40/60- versa lift, operated by a wireless handheld remote control.

Given the asymmetrical centers of gravity and varying sizes of the machinery involved, meticulous planning and critical safety measures were meticulously implemented. Every movement, down to the millimeter, was closely monitored, mitigating potential safety hazards. The successful completion of this complex rigging project showcased the exceptional expertise of our four-member crew, earning high praise from our client. As a testament to our capabilities, Beck & Pollitzer USA has been entrusted with an upcoming heavy rigging offload project by the same client, further solidifying our trusted partnership.

40,000

pound of press relocation

Critical

safety hazard planning

100%

client satisfaction