Latest News

Robotic replacement during an automotive summer shutdown

Project overview – During a recent summer shutdown in France, Beck & Pollitzer successfully replaced nine production robots in a challenging automotive manufacturing environment. With just one week to complete the project, our 20-strong team executed every stage with precision planning and flawless coordination.

Methods & tools – The project involved working within confined spaces where access was severely limited. To manoeuvre the heavy robots safely, we deployed an aluminium gantry, mobile crane, and overhead crane, each selected to ensure stability, minimal disruption, and maximum efficiency. Equipment scheduling was carefully sequenced to avoid bottlenecks and keep the installation progressing without delay.

The result – When the new robots were powered on, every installation had been fully tested and was ready to operate safely, ensuring the client’s production lines could restart without disruption. Delivering this outcome within such a short timeframe demonstrated our team’s ability to perform under extreme pressure while maintaining the highest quality standards.

The key to success – Several critical factors enabled this shutdown to succeed:

- Close team coordination ensured that every specialist worked seamlessly across shifts

- Robust project management kept activities aligned to the critical path and on schedule

- Full-time Health & Safety Coordinator on site meant that speed never compromised safety

Delivering client confidence – For our client, this project demonstrated the value of entrusting high-stakes robotic installations to a partner with proven expertise. By combining engineering capability, specialist lifting solutions, and rigorous safety leadership, Beck & Pollitzer delivered a critical upgrade on time and without incident.

Learn more about how Beck & Pollitzer supports clients during planned summer shutdowns in our industrial summer shutdown overview.

Plan your next shutdown with confidence

Whether it’s robotic replacement, large-scale equipment upgrades, or complex machinery relocations, Beck & Pollitzer is ready to turn your operational pause into lasting progress. Partner with us for your next shutdown and ensure every hour of downtime delivers maximum value.

Contact our team today to start planning your project with confidence.

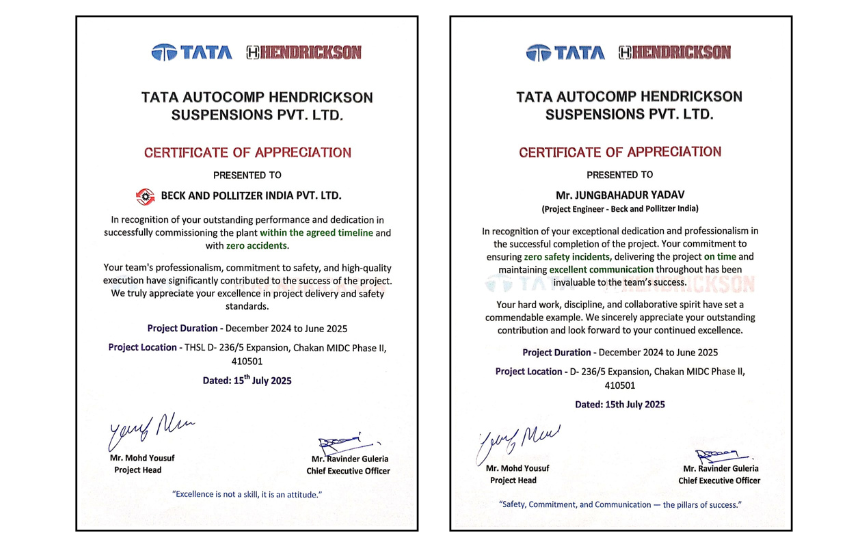

Complete body shop installation for a new EV plant in India

Intricate relocation of fragile printing equipment for a pharmaceutical leader

Precision installation for a landmark renewable energy project in India

Multi-scope upgrade during a Tier1automotive summer shutdown