Project Management

Project Management

Site management & supervision Every project – large or small – presents unique challenges. By acting as both project manager and main contractor, Beck & Pollitzer ensures every project runs as smoothly as possible. We are able to undertake the management of any kind of turnkey heavy machinery moving or installation.

We have our own team of project management experts, sometimes supplemented by specialist subcontractors. These subcontractors are always under the control of our project managers to guarantee a consistent approach.

Planning & project control The experience we have gained from tens of thousands of projects means that we can produce realistic and competitive programs of work. We integrate these with our client’s project team to deliver a successful project.

Beck & Pollitzer takes an innovative approach towards projects and we are always seeking ways to enhance our service. Our approach includes project control documentation, which tracks the progress of current projects and enables us to collate lessons learned. These lessons drive continuous improvement for future projects.

Health & Safety management Our work is managed under the current Health & Safety systems, including CDM regulations and local equivalent procedures for international projects. To read more about our commitment to Health & Safety in the workplace, please visit the Health & Safety section.

This success was possible because of the absolute professional and outstanding teamwork of the Beck & Pollitzer team… there is no other company who would have done it better.

Beck & Pollitzer has an outstanding reputation for Project Management. Our expertise includes:

- Large, complex machinery installation

- Logistically complex relocation projects

- Lifting and transportation

- Design & planning

- Risk assessment and mitigation

- Programming and scheduling

- Resource planning – labour management

- Multilingual client liaison

- Commitment to Health & Safety

Colorman press installation

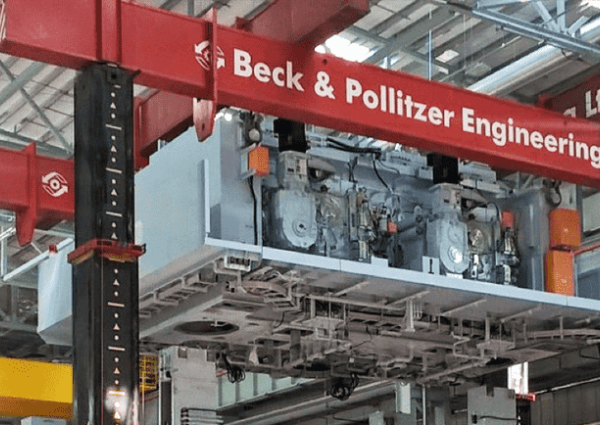

Beck & Pollitzer installed a Colorman Press for a client in Monschau, Germany. Due to unique challenges caused by the site, this particular project required intense site management, project control and planning. In order to mitigate these challenges, our team split the project into two phases.

The Press itself was installed during Phase 1. As the site was only accessible through an adjourning building, our team built an extensive track system to transport the components without disrupting the surrounding area. Limited headroom made the use of traditional methods and equipment impossible, so the team instead designed and created bespoke specialist lifting frames and attachments.

The second phase extended the press, adding 2 Colorman Towers and folders. This time, the team gained access through the side of the building and designed another load-bearing platform. Continued headroom limitations meant further specialist equipment had to be designed and built, so that the team could lift the components. Additionally, due to the position of the press extension, it was necessary to track the press elements into the building in reverse order-of-build.

Complex

logistics & method required

4

years’ duration

100%

client satisfaction