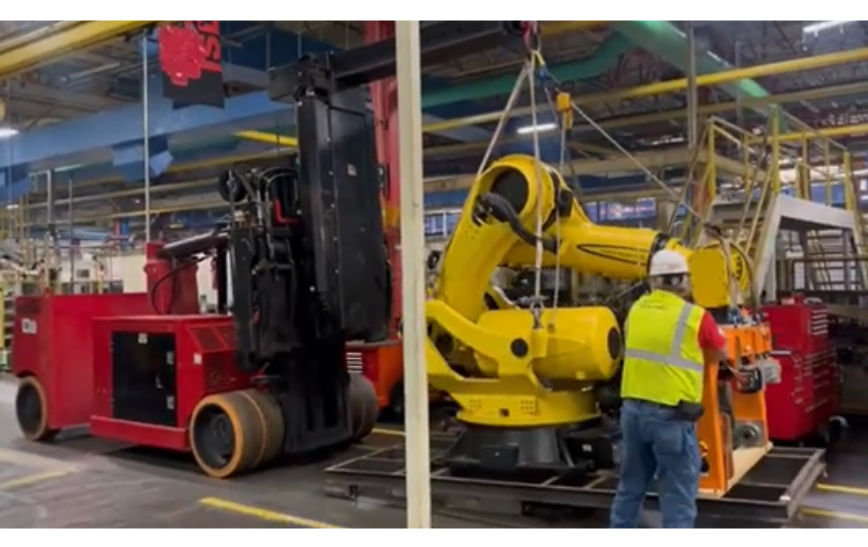

Precision Engineering Meets Heavy Lifting in Press Main Ram Housing Replacement

Challenge: Replacing the main ram housing of a massive 5100-ton extrusion press for an aluminium manufacturer in Texas, in a 3-week deadline.

Solution: Beck & Pollitzer USA deployed a 17-member team of expert riggers, millwrights, and engineers to tackle this complex machinery replacement project.

Services Performed:

Results:

Committed to delivering results, Beck & Pollitzer USA met the customer’s expectations by completing the entire project on time, adhering to safety protocols, and staying within budget. This successful industrial machinery replacement showcases our dedication to excellence in machine installation and rigging.

Facing a complex industrial machinery replacement project? Let Beck & Pollitzer expertise in rigging, machinery installation, and project management ensure a smooth, efficient, and safe operation. Contact us today for a customised solution.