Life Sciences & Pharmaceutical

Life Sciences & Pharmaceutical

Beck & Pollitzer delivers specialized installation and relocation services for the pharmaceutical, biotech, and life sciences sectors. Our global teams are trusted by the world’s leading pharmaceutical manufacturers and medical equipment suppliers to manage high-value, sensitive machinery in complex environments, including cleanrooms and GMP-regulated facilities.

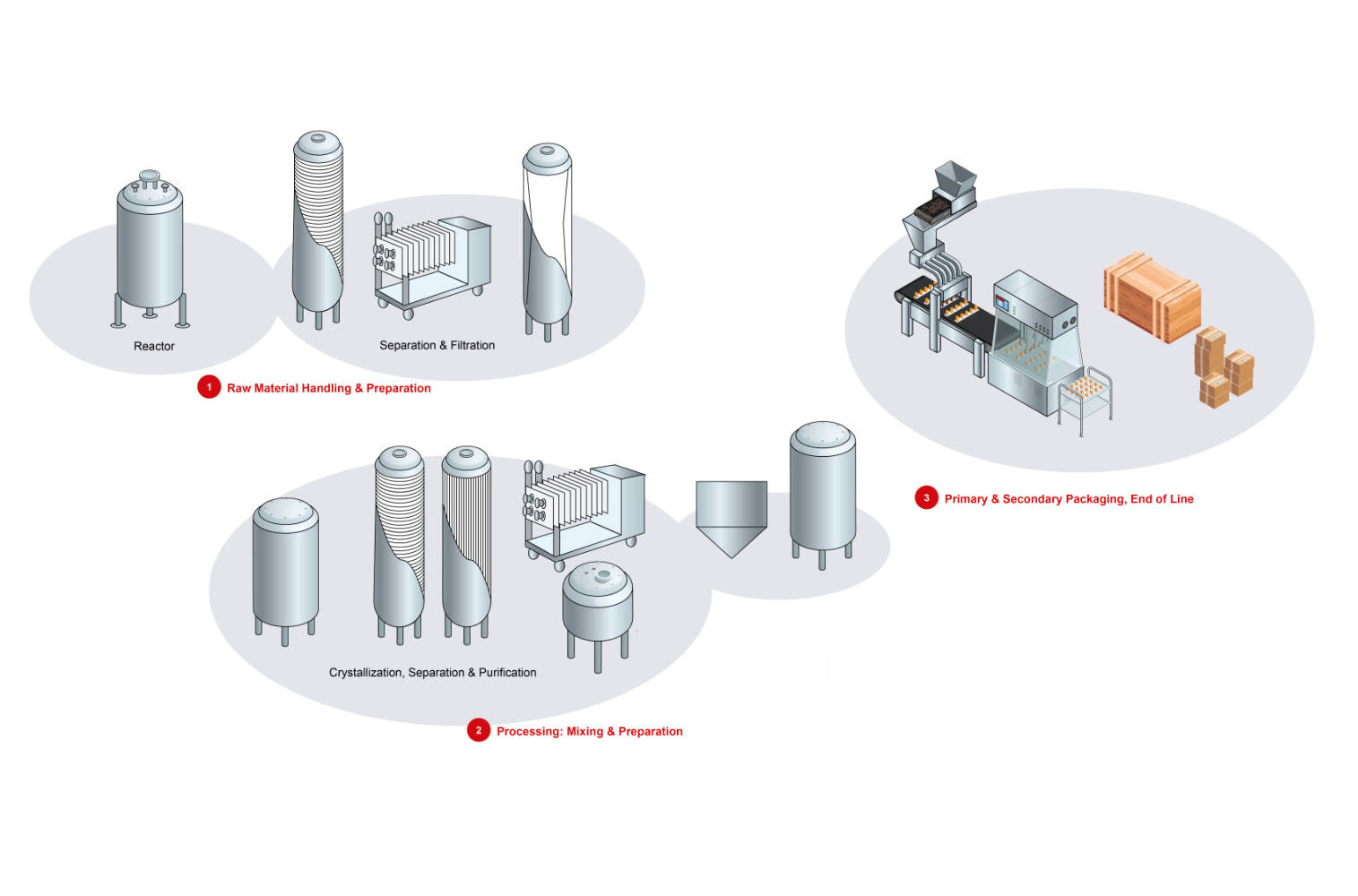

Whether it’s the installation of production lines, relocation of lab and diagnostic equipment, or decommissioning of entire facilities, our end-to-end solutions are built on safety, precision, and full regulatory compliance. Our services include:

Pharmaceutical equipment installation & relocation

We ensure reliable and efficient power delivery for your Data Centre, covering critical aspects of power infrastructure installation.Our pharmaceutical equipment specialists handle complex installations and relocations across the industry, from production lines and packaging systems to advanced medical imaging and therapeutic equipment.

Whether installing new syringe production lines, relocating vial filling systems, or positioning sensitive diagnostic equipment, including MRI scanners, CT systems, and linear accelerators, our teams deliver precision installations that meet millimeter-accurate positioning requirements.

International facility relocation & decommissioning

We offer comprehensive relocation services for pharmaceutical research facilities, including full equipment moves with phased approaches that minimise operational disruption. Our decommissioning services encompass safe dismantling of redundant pharmaceutical equipment, asset recovery, and full site clearance with proper documentation to ensure regulatory compliance.Cleanroom & GMP-compliant delivery

Beck & Pollitzer understands the stringent regulatory and contamination control requirements of GMP and cleanroom environments. Our teams work to ISO standards and follow strict clean-build protocols such as controlled access and zoning, cleanroom-ready PPE and tools, and the use of pre-approved method statements and validations.Specialist equipment expertise

We have proven experience working with high-precision, high-value equipment commonly found in pharma and life science facilities, including:-

MRI, CT, and PET scanners

-

Cyclotrons and proton therapy systems

-

Syringe and vial filling lines

-

Autoclaves, lyophilizers, isolators, and cleanroom process equipment

-

Diagnostic and therapeutic device assembly system

Why Beck & Pollitzer?

With 160+ years of industrial expertise, Beck & Pollitzer is a trusted partner to the pharmaceutical and life sciences industries. Our global network and local teams deliver complex, regulation-compliant projects with precision and consistency. We offer seamless, end-to-end project delivery from planning through installation while reducing risk, downtime, and non-compliance.To discuss your next project or request a tailored proposal, contact us.

Our services in the Life Sciences & Pharmaceutical sector include:

- Start-up support and handover readiness

- Risk assessments and method statements

- Project coordination and site supervision

- Health and safety compliance (GMP, ISO, etc.)

- Local and international equipment relocation

- Offloading, internal movement, and final positioning

- Precision levelling, alignment, and calibration

- Cleanroom-ready equipment integration

- Mechanical and electrical installation

- Cable management & cleanroom utility routing

- Strict adherence to GMP & clean build protocols

- Support for validations

- Asset recovery and site clearance support

- Specialized warehousing (climate-controlled)

- Custom crating and shock-protected transport

- Temporary staging and phased logistics

- Local regulatory compliance (FDA, MHRA, EU)

- Multilingual project support

- OEM collaboration and interface

- Global project synchronisation

- Cross-border logistics and customs coordination

Proton Beam Therapy installation in Spain

Beck & Pollitzer successfully completed the groundbreaking installation of a proton beam therapy system in Madrid, Spain. This landmark project, executed for a global healthcare giant, marked the first of its kind to be installed in Europe for the client, pioneering advanced treatment capabilities in the region.

The complex installation spanned three critical areas: the Gantry Room, Accelerator Room, and Electrical Room. Our specialized team orchestrated the precise handling and positioning of over 220 tons of highly sensitive medical equipment, a feat that demanded exceptional technical expertise and surgical precision.

The most challenging aspect involved coordinating 400-ton cranes to transport equipment through the building’s roof opening, the only viable access route for machinery of this scale and sensitivity.

Technical excellence – Beck & Pollitzer delivered complete turnkey installation services, including:

-

Millimetre-perfect alignment and positioning of all therapeutic equipment

-

Comprehensive mechanical, electrical, and instrumentation integration

-

Installation of over 40km of specialized cabling systems

-

Full commissioning support to ensure optimal system performance

The ultra-sensitive nature of proton beam technology demanded unwavering precision at every stage, with our team maintaining the exacting tolerances required for life-saving medical applications.

Ensure precision on your next critical infrastructure project. Contact our specialist team to discuss your project.

Full

Turnkey Project

High

Quality Control expectations met

New

Technology and high-tech equipment

Replacement of robotised underbody production line

One of the biggest automobile manufacturers trusted us with the replacement of an underbody line including fourteen pieces of robots and ten pieces of robot bases at a welding shop in Czech.

The replacement project included electrical and mechanical…

Installation of underbody lines for an automotive manufacturer

Beck & Pollitzer France completed the installation of the Mild-hybrid (MHEV) project of the underbody lines for a multinational automotive manufacturer.

The main task of this project was to relocate, integrate and install various equipment and m…

Plant relocation for the global automotive part manufacturer

Clarkson Industrial, part of Beck & Pollitzer Group was awarded a challenging and complex project to relocate Tier 1 components production facility from South Carolina to Texas in four phases from 2019-2020. The Global Automotive part manufactur…