Warehouse Automation

Warehouse Automation

In the fast-growing Warehouse Automation sector, Beck & Pollitzer has established itself as a global leader. Thanks to our standardised methods, we deliver quality installations in multiple geographies for our blue-chip customers. We have gained experience in all types of storage systems. By seeing beyond the blueprint, Beck & Pollitzer can customise innovative warehouse automation solutions to your needs and anticipate challenges such as supply chain disruptions, saving you both time and money. With Beck & Pollitzer on your side, you can stay one step ahead of the competition.

Automated warehouse installations

With advances in latest technology, the possibility of increased efficiency and reduced operational costs, Warehouse Automation is the next step in ensuring efficient logistics flow. Warehouse automation brings in a variety of benefits ranging from low operating cost, better space utilisation, increased productivity and reduction in picking errors, delivering increased ROI and safer operations. Read more about automated warehouses, latest trends & benefits here.For most clients, the shift to automation is a global endeavour, with a large number of warehouses being transformed around the world in a short period of time. Beck & Pollitzer’s global network allows to roll out a standardised program of installations, ensuring a high level of quality and commonality on all warehouse installations.

Bespoke Warehouse Automation solutions

Depending on the requirements of your automation project, we will provide a full service, from delivery to commissioning and our expert team will fine-tune the installation process each time to increase scalability.Beck & Pollitzer is leveraging its global network of operational offices to support the fast deployment of automated warehouse around the world. Our standard processes, attention to quality and geographic spread allow us to follow OEMs and customers around the world to deliver on-time installations, reducing the need for commissioning and fault finding, and supporting earlier “Go Live” production dates. As a certified AutoStore installer with unparalleled expertise, we flawlessly execute AutoStore system implementations. Our dedicated and talented professionals are ready and willing to meet your every challenge by working collaboratively with you to find the most cost-effective installation solutions.

Discuss warehouse & logistics automation needs with us

When it comes to Warehouse Automation Beck & Pollitzer brings unmatched expertise and extensive experience to deliver projects successfully on time. We look forward to assisting you with all your Warehouse Automation needs while staying on time, on task and on budget. Contact your local branch!

Our set of Warehouse Automation services include:

- Health and safety management

- Project control

- Site management and supervision

- Offloading

- Material management & logistics

- Floor marking

- Primary and pre-assembly

- Final set up of grids

- Precision lines & level

- Pick up and retrieval stations

- Robot loading

- Support to commission

- Bin / Tote inductions

- AutoStore Installations

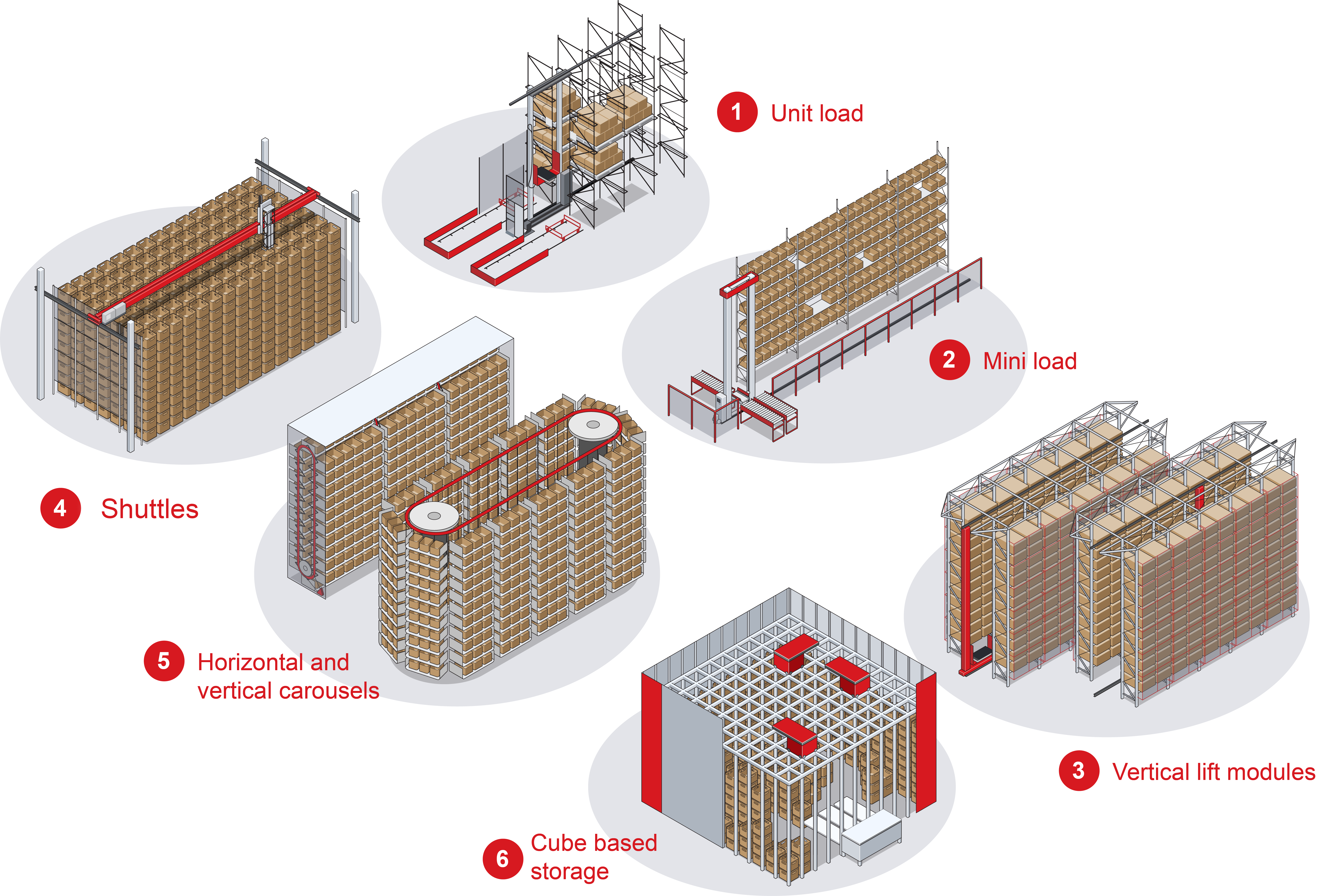

Warehouse Automation Experts in all types of storage systems

Innovative approach to Warehouse Automation

Beck & Pollitzer was contracted to install a medicine supply automated warehouse system for a global logistics automation company in the USA. The installation consisted of a 3956 cells autostore system, including platforms and pick up cells.

Beck & Pollitzer USA developed a standardised method of installation, using a bottleneck approach to improve takt time from 120/5/day to 280/6/day. We received praises from both customers for the accuracy of the installation and the novel approach to delivery.

Following successful handover of the, Beck & Pollitzer became an Autostore preferred supplier – we were awarded numerous installs including the largest auto store in North America. Beck & Pollitzer USA has now installed Autostores in 5 different states and is continuing to provide superior service in the sector.

We have currently managed numerous Warehouse Automation projects like this and our team of engineers and project managers are always keen to share their knowledge and experience with our clients. For further information on how we can help you, call our local Beck & Pollitzer office.

3956

cells auto store installed

Innovative

approach

to delivery

100%

client satisfaction

Beck & Pollitzer earns global AutoStore Installer Accreditation

Having first gained accreditation in 2021 in the USA, Beck & Pollitzer is proud to announce that it has expanded its geographical reach of the prestigious AutoStore Global Installer accreditation. This significant milestone signifies the company…

Installation of ASRS Systems at an e-grocery fulfilment centre

Once again, Beck & Pollitzer USA teamed up with one of their leading fulfilment technology partners and showcased their expertise in warehouse automation by installing an extensive Automated Storage and Retrieval System (ASRS) for one of the nat…

Installation of ASRS Systems at an e-grocery fulfilment centre

Once again, Beck & Pollitzer USA teamed up with one of their leading fulfilment technology partners and showcased their expertise in warehouse automation by installing an extensive Automated Storage and Retrieval System (ASRS) for one of the nat…

Installation of automated storage & retrieval system

Beck & Pollitzer continue to answer the demand for warehouse automation and remain a fulfilment leader by installing goods-to-person automated storage and retrieval systems, also known as Autostores.

We have been awarded an extensive Autostore i…

Installation of an automated warehouse for a production plant

Beck & Pollitzer undertook another warehouse automation project for a dairy producer, which was completed successfully on time.

The task included the installation of a fully automated warehouse system, which will operate at a very low temperatur…

Installation of automated storage & retrieval system in Ohio, USA

Beck & Pollitzer undertook a project of installing automated storage and retrieval system (AS/RS) in Ohio, USA, for a giant in the FMCG industry. The project’s scope of work included installing 19 aisle cranes and associated pallet conveyors – u…