Latest News

Comprehensive engineering services from FAT to commissioning support

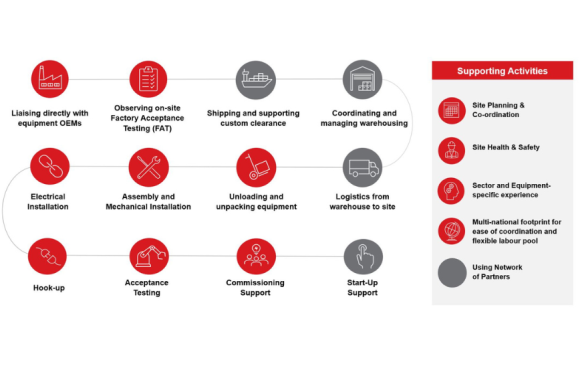

At Beck & Pollitzer, we offer end-to-end engineering services that support clients across all stages of their industrial installation and relocation projects. From Factory Acceptance Testing (FAT) to commissioning support and everything in between, our process-driven approach ensures seamless delivery, safety, and efficiency across multiple industries.

Full-service engineering and industrial support across the project lifecycle

With over 160 years of experience and a presence in 4 continents, Beck & Pollitzer has built a reputation for managing complex, large-scale engineering projects across sectors like automotive, logistics, manufacturing, EV, warehouse automation, FMCG, and more.

We understand that every project is unique. That’s why our turnkey engineering services are structured to support every stage of your project:

- Initial stages: We begin by liaising directly with equipment OEMs, ensuring a clear understanding of your requirements. Our meticulous site planning and coordination, combined with rigorous risk assessment and H&S compliance management, set the foundation for a successful project. We also manage resources and labour effectively, ensuring your project is adequately staffed.

- Factory Acceptance Testing (FAT): We provide on-site observation and support during Factory Acceptance Testing (FAT), ensuring equipment meets the required specifications before shipment.

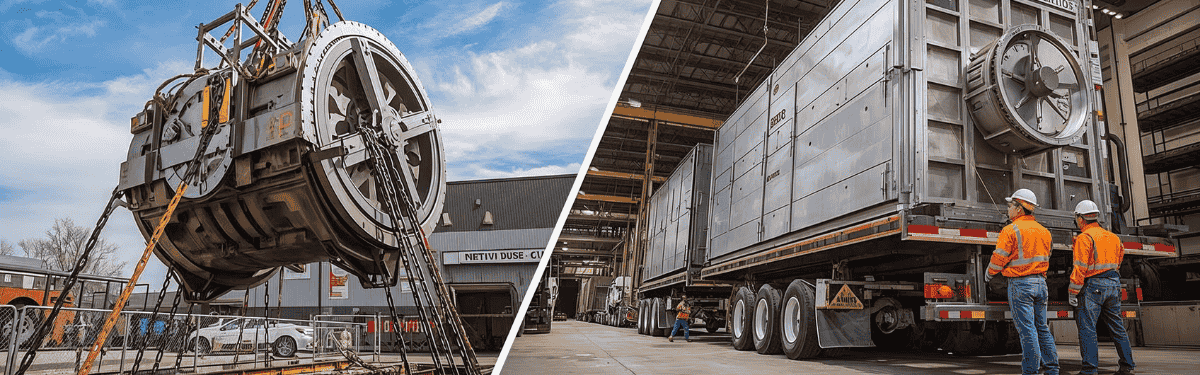

- Logistics & shipping: Our services extend to shipping and supporting custom clearance, coordinating and managing warehousing, and handling the logistics of moving equipment from the warehouse to the site. This includes running temporary warehousing close to where installations take place and coordinated all activities from initial arrival to setting-in-place.

- Installation & assembly: Our skilled teams handle the unloading and unpacking of equipment, followed by expert installation and mechanical assembly, and precise electrical installations. We also offer piping and steelwork design and installation.

- Final stages: We provide hook-up services, acceptance testing, and commissioning support, ensuring your equipment is ready for operation. Our start-up support helps you get your production lines running smoothly.

- Ongoing support: Beyond the initial installation, we offer maintenance support, commissioning support & verification checks and specialist machinery modification. Check the full list here: https://beck-pollitzer.com/services/specialist-services/

Supporting activities: Throughout the entire process, we provide crucial supporting activities, including:

- Project management: Experienced project managers oversee every aspect of the project, ensuring efficient execution and clear communication.

- Site health & safety: We prioritise safety, implementing strict health and safety protocols to protect our workforce and your facility.

- Sector and equipment-specific expertise: Our teams possess in-depth knowledge of various industries and equipment types, ensuring tailored solutions.

- Multi-national footprint: Our global presence allows for ease of coordination and a flexible labour pool, enabling us to handle projects of any scale, anywhere in the world.

- Using network of partners: We leverage our network of trusted partners to provide specialised services and resources as needed.

- Local & on-site logistics: We provide lifting and transport, storage & storage management, packaging and conservation, and oversized equipment

- Specialist service: We also offer metrology/laser tracking, maintenance support, and specialist machinery modification.

Why Beck & Pollitzer? With over a century and a half of experience, Beck & Pollitzer offers a unique combination of expertise, global reach, and a commitment to excellence. Whether it’s a conveyor installation, equipment relocation, or an entire factory move, our comprehensive capabilities—from planning to commissioning—make us a trusted partner for industrial engineering projects worldwide. Contact Beck & Pollitzer today to explore how our tailored solutions can streamline your next project. Get in touch →

The comprehensive guide to millwrights: Definition, role, and importance

Equipment decommissioning: Safely retiring machinery & production lines

Machine moving and rigging: From dismantling to installation

Industrial summer shutdowns: When Beck & Pollitzer is at full speed