Factory Relocation

Factory Relocation

Factory relocations are some of the most challenging projects a machinery company can undertake. To ensure a client’s factory relocation project is a success, they must keep disruption and downtime to an absolute minimum, as well as meeting cost and timescale expectations. These complex factory and plant relocations require expert knowledge and experience, which often means bringing in an external specialist company.

150+ years experience with factory & plant moving

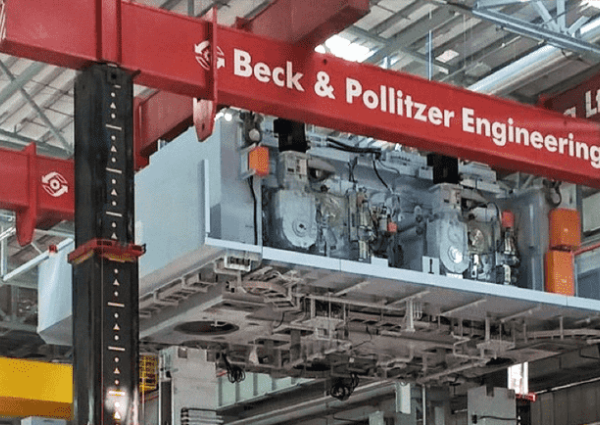

Beck & Pollitzer has over 150 years of experience with factory moves, equipment and machine relocation projects, including full turnkey factory relocations. From plant dismantling and disconnecting existing factories, to transporting them and reassembling and installing them at a new site—sometimes in a different country halfway across the world—we have the expertise necessary to complete such industrial projects successfully.International factory & plant relocation

A factory relocation can be complex and challenging, which is why it is vital that companies use professionals with the experience and knowledge to complete it successfully. The dangers of late delivery, or incorrect installations can cause severe disruption and potential financial losses for clients, which is why it is vital to get it right first time.As one of our core services we are able to assist with all your factory and plant relocation needs across Europe and often globally. With over 30 offices in 17 countries, including Russia, Turkey, India, USA and Australia, Beck & Pollitzer has the unique advantage of being able to carry out most international relocations with local teams on each side. We are particularly experienced in projects requiring dismantling in one country and then transport and installation in another. This is backed up by our extensive experience, completing thousands of machine installation and relocation projects annually, and multiple satisfied customers worldwide.

Our typical factory relocation and plant removal services feature

Whilst some of our competitors may approach your factory move with a ‘lift and shift’ mentality we take a completely different perspective. Working in partnership with you we will minimise the disruption to your operations and provide technical guidance where possible to help streamline your new setup. In addition to manufacturing and installation of floor plates, walkways and access platforms, we also provide mechanical installation including any rebuilding along with the installation of guards or ancillary equipment.Safety is our highest priority for all our factory and plant relocation projects. Our experience and standardised approach minimise the risks involved in moving or installing large equipment. Before we move any piece of equipment, and during every stage of every project, we carry out thorough health and safety planning and audits which include Risk assessment, Method statement, Job safety plans, Process validation, Weekly & monthly reporting, Inspection tags & pre-task analysis, Internal audits, Safety awareness trainig, Daily safety walks & talks.

Since every project is different, we will provide you with a scope of services tailored to fit your requirements. To discuss all your factory relocation and plant removal needs please contact our local office for further advice and assistance.

Always putting safety first but working with us to understand our needs and priorities to ensure we can still be operational through the move/fit-out.

Summary of Beck & Pollitzer factory and plant relocation services:

- Dedicated factory relocation Project Manager

- CDM/Health and Safety Management

- Existing machinery removal

- Match marking and optional 3D scanning

- Disconnection and reconnection of primary supplies

- Packing and Shipping

- Datum surveys and alignment checks

- Preparation of foundations and footings

- Floor marking and positioning checks

- Drilling and preparation of floor fixings

- Storing and moving machinery to site

- Heavy lifting into position with our fleet: hydraulic gantries, forklifts, versa lifts, twin lifts etc

- Alignment and levelling

- Mechanical & electrical services

- Testing and pre-commissioning work

- Final commissioning work in conjunction with client and/or OEM’s

- Handover to client and documentation

Successful completion of full turnkey factory relocation project

Beck & Pollitzer undertook a major factory relocation from Coventry to new purpose-built facility in Leamington Spa, Warwickshire UK, for a blue-chip client in the Green Energy sector. In addition to full project management services for our client, we also carried out the role of Principal Contractor for the full plant removal, relocation and installation project.

We provided a full turnkey factory relocation solution which included the relocation of the production machinery, test cells, R&D facility and combustion chambers with the mechanical and electrical disconnection and reconnections. In addition, we carried out the installation of primary supplies within the new factory which included 24KM of data cables.

Beck & Pollitzer’s, full project management services ensured that the machinery was disassembled, transported and reinstalled safely, efficiently and with minimum impact on manufacturing. Along with our standard mechanical and electrical installations and relocation services, our expert team also sourced, and project managed a key number of sub-contract services which included:

- New Mezzanie Floor

- New Internal Offices, Rest Rooms and Welfare facilities

- New Floorings and decorating of walls and ceilings

- Also carried out and completed was the de-Lap repairs on client’s old facility

Under the supervision of our project manager, the project was carried out on schedule and to the client’s complete satisfaction and with a 100% focus on health and safety.

Our client comment: “I can’t praise Beck & Pollitzer enough for the work they have done in getting us to where we are now and keeping to timing and budget whilst working with us to keep manufacturing going and ever-changing requirements. The dedicated Beck & Pollitzer team has led the project from day 1 and has worked with us every step of the way, safety absolutely the number 1 priority but working with us on our sometimes outrageous requirements and delivering”.

Full

turnkey project

High

quality control

High

Collaboration with other companies

100%

Client Satisfaction