Battery and Electrification

Battery and Electrification

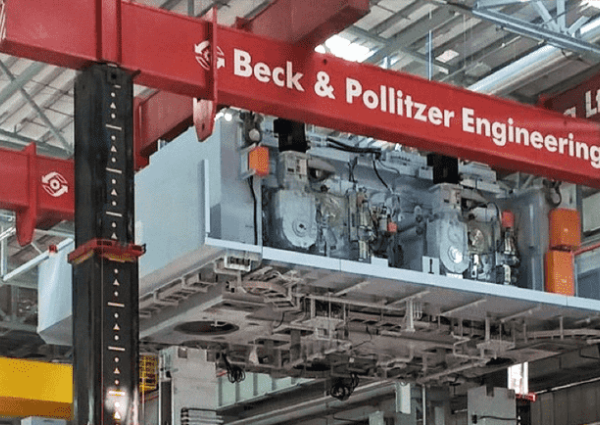

The world is electrifying, and Beck & Pollitzer is at the forefront, providing comprehensive Engineering Services, that encompass the installation and relocation of advanced equipment, to propel the Battery and Electrification industry forward. As a global leader with over 160 years of experience in Engineering Services , we understand the unique challenges and opportunities this dynamic sector presents.

Our services include:

Battery production line installation & relocation:

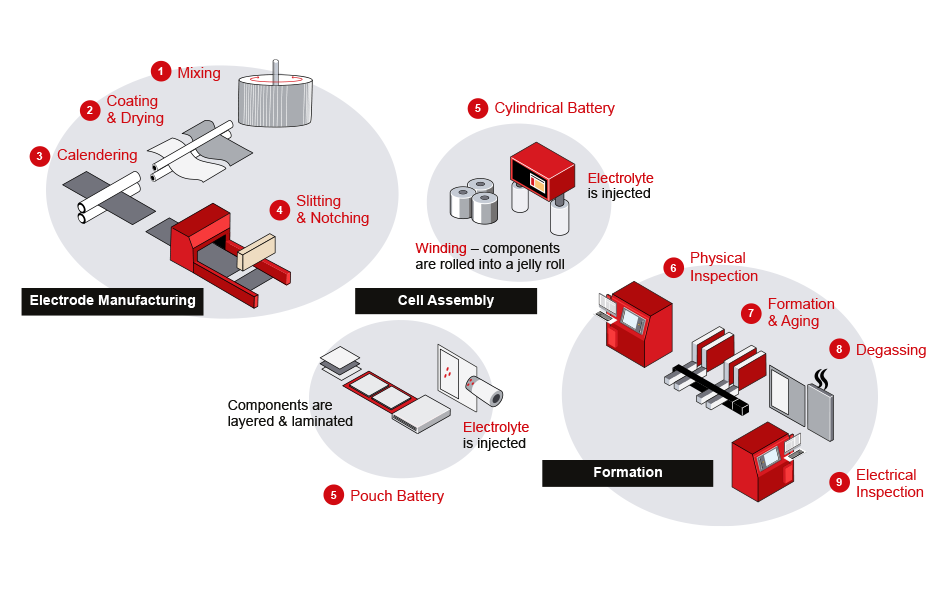

From intricate cell assembly lines to massive battery module production facilities, we seamlessly manage the installation, relocation, and modification of your equipment, minimising downtime and optimising your production flow.Our expertise extends to all machinery used in electric car battery production, including electrode manufacturing, cell stacking, welding, formation, aging, and battery pack assembly. We ensure precise and efficient setup and transitions, leveraging cutting-edge technology and best practices to support the evolving needs of the electric vehicle industry.

Press line & Body-in-White installation:

Our team possesses unparalleled expertise and resources to handle the precise installation and alignment of press lines and body-in-white systems for efficient and accurate electric vehicle assembly.Our EV press line installation service includes high-tonnage stamping presses (transfer/draw presses) for complex body panel forming, along with automated feeding systems (coil feeders/blank loaders) and robots for material flow. We ensure precise die alignment with laser trackers for consistent panel quality. Additionally, our BIW system installation covers robotic welding stations (spot/laser/seam welding) and automated fixturing systems for accurate EV body assembly, with advanced vision systems guaranteeing top weld quality.

Modifications for hybrid & electric Body-in-White:

Transitioning your existing production line to accommodate hybrid and electric vehicle (HEV/EV) variants requires precise modifications to the Body-in-White (BIW) stage. We provide expert planning, engineering, and execution for seamless modifications.Our services include the installation and integration of specialised equipment such as resistance welding machines, laser cutting systems, and automated guided vehicles (AGVs). We handle all aspects of the transition, from structural reinforcements to electrical system upgrades, ensuring your production line is future ready.

Electrical integration:

Our electrical installation services encompass comprehensive electrical infrastructure solutions. This includes meticulous routing design and precise cable sizing based on detailed calculations. We supply and install the necessary support structures, power, and IT cables, connecting them seamlessly from the distribution cabinet or busbar to process cabinets. Our expert team ensures a robust electrical system which complies with all safety and regulatory standards and is tailored to the specific requirements of your battery or EV production facility.Logistic management:

We offer comprehensive logistics support tailored to the unique demands of your battery and EV projects. Our services encompass external storage solutions, efficient container and truck unloading, meticulous unpacking, responsible waste management, secure equipment transport to the final site, and precise positioning within your factory. Our experienced team coordinates every step, ensuring your equipment is delivered on time and in perfect condition, minimising operational disruptions and optimising workflow efficiency.Ready to partner with the Battery & Electrification experts?

Beck & Pollitzer stands ready to empower automakers and OEMs with the expertise they need to navigate this shift. From electric vehicle manufacturing to infrastructure development, Beck & Pollitzer’s precision engineering contributes to the growth of clean and renewable energy sources. Contact Beck & Pollitzer today to discuss your specific needs and embark on a journey towards a sustainable and thriving future in the electrifying world.

Our set of EV and Battery services include:

- Health and safety management

- Project control

- Site management and supervision

- Offloading

- Material management & logistics

- Floor marking

- Primary and pre-assembly

- Final set up of grids

- Precision lines & level

- Pick up and retrieval stations

- Robot loading

- Support to commission

- Storage of equipment

- Heavy machinery dismantling and reassembly

- Alignment and positioning of equipment

- Mechanical and electrical integration

- Hydraulic and pneumatic connections

- Vibration and shock testing during installation

- Electrical panel installation

- Cable management and routing

- Control system integration

- PLC (Programmable Logic Controller) integration

- Electrical testing and validation

- Electrical troubleshooting and diagnostics

- Commissioning and handover support

Battery and Electrification

The world is electrifying, and Beck & Pollitzer is at the forefront, providing comprehensive Engineering Services, that encompass the installation and relocation of advanced equipment, to propel the Battery and Electrification industry forward. As a global leader with over 160 years of experience in Engineering Services , we understand the unique challenges and opportunities this dynamic sector presents.

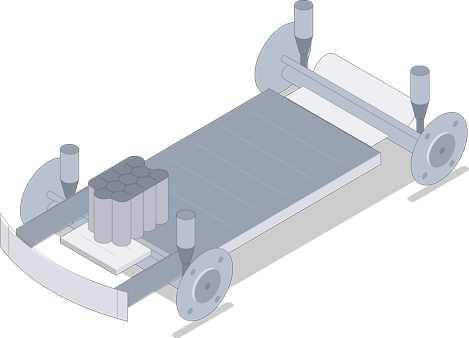

Beck & Pollitzer enables the evolution of Manufacturing lines towards full electrification

Battery Cells

Underbody

Powertrain

-

Underbody

-

Battery Cells

-

Powertrain

Battery Cells plant installation

Installation of process equipment for the manufacturing of rechargeable batteries – Beck & Pollitzer USA was awarded their biggest project to date.

Our client has created the plant with plans to accelerate the world’s transition to sustainable energy. They plan to do this through increasingly affordable electric vehicles and energy products. Beck & Pollitzer oversaw the installation of process equipment for the manufacturing of rechargeable batteries for the Automotive giant.

Challenges included the installation of a large Anode Dryer System in tight quarters and working around multiple contractors/trades, as well as working on 3 floor levels simultaneously. However, these challenges were successfully overcome through strategic planning and excellent staff organization. And the maintenance support we continue to provide this client is helping them take a step closer to achieving their aim of bringing affordable electrification to the world.

5 years

Continued presence

High

Collaboration with multiple stakeholders

120

Operatives on site

Complete body shop installation for a new EV plant in India

A leading global automotive manufacturer recently inaugurated a major new electric vehicle (EV) assembly plant in Tamil Nadu, India – a strategic milestone in their international expansion. As part of this flagship project, Beck & Pollitzer was…

Decoding Gigafactories: The future of electric vehicles

Gigafactory: Your questions answered – How big? How powerful? How sustainable?

The name itself evokes images of immense scale and cutting-edge technology. These massive facilities are at the heart of the electric vehicle (EV) revolution, producing t…

Powering the future: Beck & Pollitzer delivers battery plant

Our client, a European automotive battery leader, sought to establish a state-of-the-art battery cell plant in France to decarbonise automotive battery production. They required a partner capable of handling the complex electrical integration and in…

Battery manufacturers supply chain

Battery manufacturers: Is your supply chain ready for growth?

From the mobile devices we use to the vehicles we drive, the world is becoming ever more reliant on battery power. And demand is growing at an electrifying speed.

Batteries are key to ach…

What it takes to create a Gigafactory

Gigafactories — the long, hard road from announcement to delivery.

‘We are proud and delighted to announce….’

Barely a week goes by without someone declaring to the world’s press that they’re establishing a new Gigafactory in China, Europe, or the U…

Installation of NMP Recovery unit

How to accurately position an NMP recovery unit in a location with restricted headroom? That was the latest challenge Beck & Pollitzer UK faced as they continue to help build a greener future by supporting clients working in battery power and el…