Machinery Movers

Machine shifting: Heavy machinery moving & relocation services

Beck & Pollitzer is one of the market leaders in heavy equipment moving and relocation. Our highly skilled professionals work alongside our clients’ teams to move and relocate your heavy machinery and equipment, with minimal disruption to operations.

We know that as businesses grow and adapt, so do their machinery requirements, and we’re here to assist clients who find themselves needing to modify their existing machinery and equipment assembly. With our years of experience, we recognise that no two projects or clients are the same, so our services can be flexible and tailored to meet the unique needs of each company we work with.

Machine erection & moving services with 150+ years of experience

Over the last 150 years we have grown as a company, honed our skills and built an unrivalled knowledge of the requirements for heavy machinery moving. Our clients are always in safe hands when they engage our services. From moving equipment and machinery within a factory, to machinery transport and the entire relocation of production facilities across countries, we have the experience, tools, expertise and safety measures to ensure every project goes smoothly.What our clients get from a machine moving project

Clients who engage our machine shifting services will be supported through every step of the project. You will have one point of contact for every part of the project.-

Health and safety planning and audits.

-

Our teams will work to dismantle your machinery and mark each component, and if re- assembly is required at a later stage, these processes will be documented.

-

Dismantled machinery will then be lifted and loaded into the transportation vehicles using our specialist fleet of Hydraulic Gantries, Versa Lifts and Fork Lift Trucks.

-

Once the equipment is loaded, it can then be transported to its new location as required, along with the management of any road or vehicle permits needed for international travel.

-

At the end destination, the machinery will be unloaded, and re-installation will be undertaken if needed. You can find out more about our machine installation services here.

Why choose Beck & Pollitzer for moving machinery

> Our expertly trained and professional industrial movers boast a range of specialist skills to carry out projects no matter their size or complexity. Our engineers are trained to approach every project with a flexible and open outlook. Our expert team of heavy machine movers keep up to date with the latest technological and transportation developments to ensure we can meet the ever-changing demands of our varied clients and their businesses.Our machinery movers don’t just ‘lift and shift’

Whilst some of our competitors take a ‘lift and shift’ approach, we like to look at our projects holistically. While moving from A to B is important, we always think about the impact that journey will have on all aspects of a business.We work in partnership with our clients to ensure every eventuality is prepared for, our clients are engaged at every touchpoint and any disruption to production is minimal. With this 365-degree approach, and our extensive experience to lean on, we are often able to identify and troubleshoot any potential issues, before they arise. This means that projects run efficiently, safely and securely.

Accurate machinery transportation & laser tracking

Having capable machine transporting tools is a key component to safe machine relocation. But in this day and age, machinery is heavy and more sophisticated than ever, so accuracy plays an important role successful transporting. Beck & Pollitzer provides metrology (laser-tracking) – our in-house systems cater for floor-marking, alignment, measuring and levelling to ensure pin-point precision throughout the process.International machinery movers

Heavy machinery moving is one of our core services, this means we carry out our removal and relocation services across continents and worldwide. The process of dismantling machinery, transporting and reassembling it in another country is well within our capabilities. In addition to moving machinery, we also have the experience and expertise to provide help with full turnkey factory relocation projects.Safety, security and efficiency are our priority

Machinery relocation projects that are unsuccessful, incomplete or late can cause huge disruption to a business’ productivity and potentially financial loss. That is why we take the planning and efficiency of our machine moving projects seriously. Our project managers are keen to share any knowledge and experience from previous projects to create robust plans with future clients.We also recognise that machine moving can involve dangerous situations, so the safety of our employees and those of the clients we work with is an extremely important part of the project process. Safety regulations and measures are looked at in detail to avoid potentially hazardous situations and project slip-ups.

Discuss machine relocation or removal needs with us

To discuss your relocation or removal needs please contact us for further advice and assistance.Despite considerable complications, Beck & Pollitzer still managed to complete the project within the allotted schedule and without any downtime. Highly recommended!

Summary of Beck & Pollitzer machinery moving services:

- Dedicated project manager

- Transportation to its new location both nationally and internationally including managing any road permits etc

- Handover to client and documentation

- Customised and quality-assured services

- Risk assessments

- Multilingual client liaison

- Detailed method statements and pre-lift planning

- Liaison with Local Authorities

- Placing loads into final positions

- Route planning & logistics

- Unloading at destination and then undertake re-installation phase if required

- Removal and loading onto transportation as necessary

- Logistically complex relocation projects

- Packing machinery depending on transport requirements

- Internal reorganisation

- Designing single machine moves

- Dismantling of machinery including documenting the process and marking components if re-assembly is required at a later stage

- Removal of floor fixings

- Removal of walkways, access platforms and other infrastructure

- Disconnection of electrical and mechanical connections

- Decommissioning of existing machinery

- Match marking of mechanical, electrical and piping parts

- Custom equipment relocation

- CDM/Health and Safety Management

Machine relocation from France to Italy

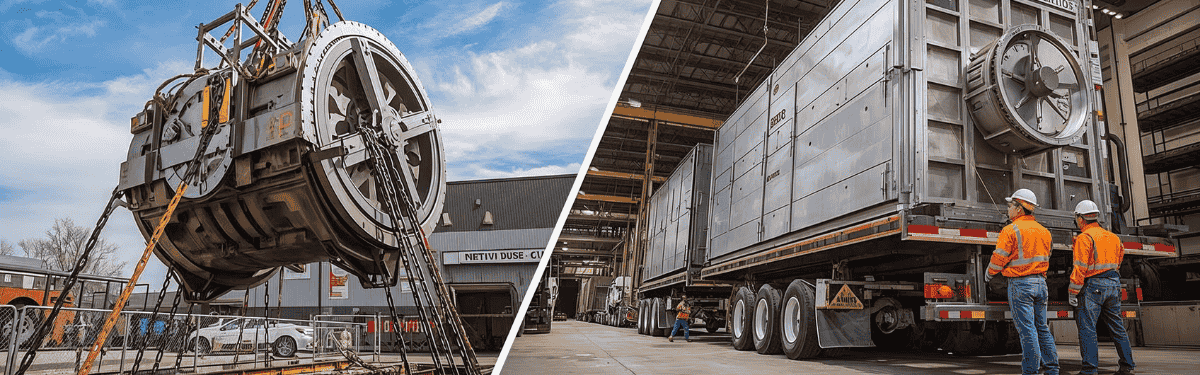

The French arm of the Beck & Pollitzer business has successfully completed a machinery transport project for a renowned international group specialising in food packing for prestigious brands.

Despite the large machine transportation and relocation project having a number of logistical obstacles, our team managed to complete the job in two succinct phases.

The first phase consisted of disassembling three cutting machines, known as “Leopard”, “Baghera” and “RB4”.

-

The Leopard was packaged up, loaded and transported to their logistics centre for storage.

-

The RB4 was also packaged up, loaded but then transported to their supplier in Italy for a revamping, before shipment to their factory in the Netherlands.

-

The Baghera was received by our team, unpacked and installed in place of the previous machinery.

The second phase of this heavy equipment moving project consisted disassembling and reassembling the “Tiger”, the final cutting machine, and also the dismantling and removal of the Baghera, which was only in place temporarily. The Baghera was then taken to the logistics centre for storage.

In order to maximise efficiency, the team faced the challenging task of trying to coordinate the dismantling and reassembly operations with the reception and dispatching of other machinery. They also had to factor in the logistics of transporting our own equipment which included a platform, crane and 3T forklift. Thanks to the expertise of the Beck & Pollitzer technicians, none of the operations were hindered or delayed.

If you’d like to find out more about how our machinery and equipment movers could help your business and its relocation needs, please contact us for further advice and assistance.

500

Project hours

Strict

Schedule met

High

efficiency

100%

Machine moving and rigging: From dismantling to installation

Difference in rigging and machine moving

When factories expand, upgrade, or relocate, one of the biggest challenges is safely moving heavy machinery. This is where machine-moving and rigging services come in. It’s not just about transporting equipme…

Relocating pharmaceutical autoclaves for a global healthcare leader

Client profile: Our client, a leading global pharmaceutical manufacturer, is recognised for its world-class research, innovation, and large-scale production of life-saving medicines and healthcare solutions. With facilities across multiple continent…