Metals & Minerals

Metals & Minerals Services

The metals and minerals industry forms the foundation of global manufacturing and infrastructure development. Beck & Pollitzer delivers comprehensive Engineering Services that encompass the installation, relocation, and decommissioning of heavy industrial equipment.

Beck & Pollitzer’s expertise extends to specialised metals and minerals installation services, encompassing the full spectrum from initial lifting and rigging to intricate mechanical and electrical installations. Our partnership approach fosters long-lasting relationships with metals producers, mining companies, and equipment manufacturers, ensuring seamless collaboration and successful project delivery.

Our comprehensive range of metals & minerals services includes:

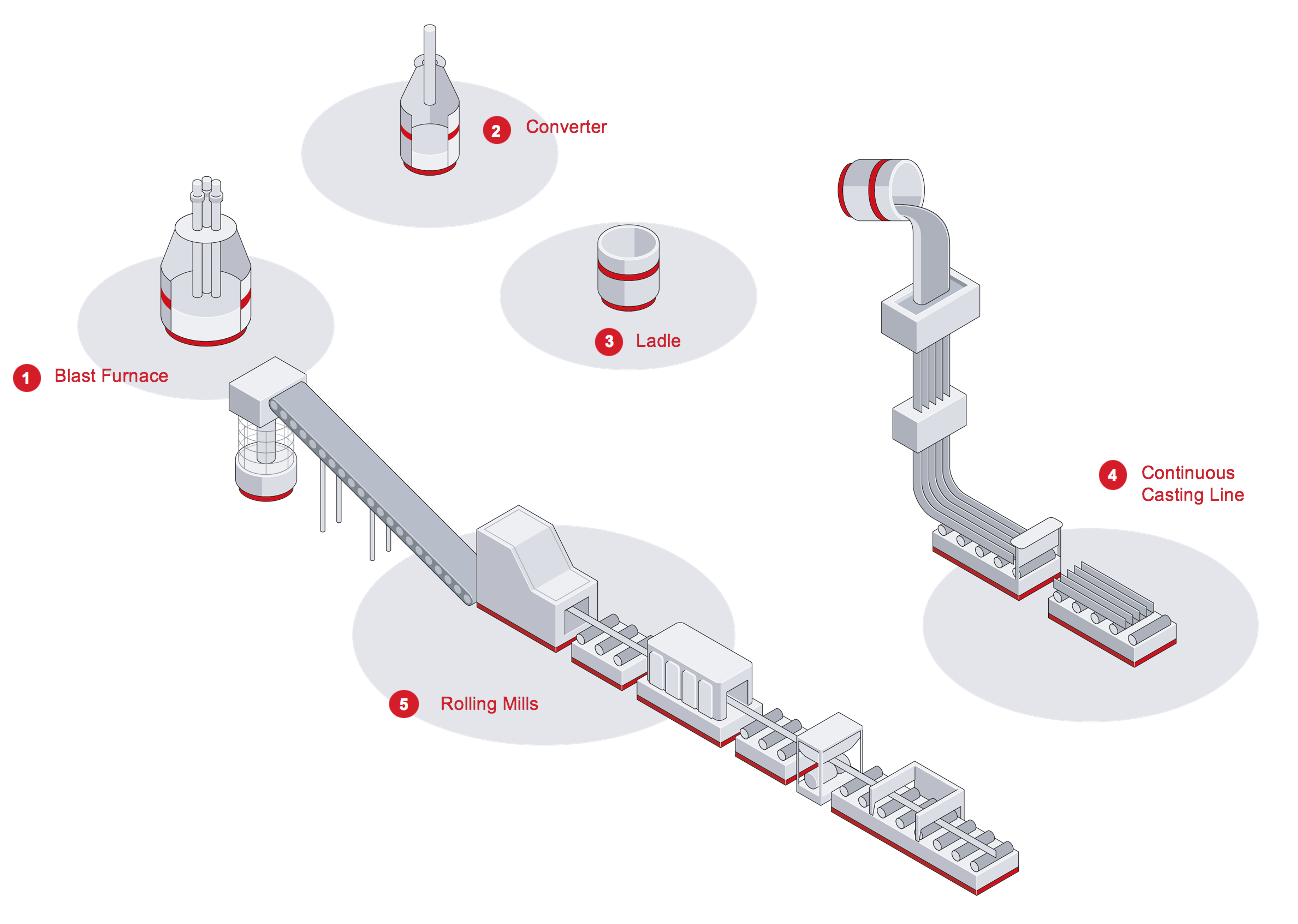

Heavy equipment installation & relocation: We handle the precise installation and alignment of blast furnaces, electric arc furnaces (EAF), submerged arc furnaces (SAF), continuous casting machines, rolling mills, crushers, ball mills, flotation cells, and magnetic separators. We ensure precise positioning with laser tracker alignment for optimal performance.

Cooling and water systems: Installation of cooling water systems from distribution networks to casting equipment, including emergency water supply systems, recirculation pumps, cooling towers, and heat exchangers essential for metallurgical processes.

Media supply and piping systems: Complete installation of media supply pipelines, compressed air systems, nitrogen supply lines, oxygen supply systems, and hydraulic fluid distribution networks, which are critical for metals processing operations.

Structural and mechanical work: Comprehensive mechanical installation services including steel structure assembly and erection, equipment anchoring and levelling, shimming and precision alignment, and installation of holding bolts and foundation systems.

Electrical and instrumentation integration: Our electrical installation services encompass comprehensive power distribution solutions for high-demand industrial environments. This includes cable routing and installation, control system integration, and instrumentation setup, ensuring a robust electrical infrastructure that complies with industrial safety standards.

Commissioning and decommissioning support: We provide expert commissioning assistance, including cold function tests, performance verification, and comprehensive documentation. Our decommissioning services include equipment dismantling, cleaning of solidified metals, and complete relocation to new facilities.

Connect with Beck & Pollitzer:

With a proven track record of delivering high-performance metals and minerals projects for leading global organisations, Beck & Pollitzer is ready to support your next installation, relocation, or decommissioning project. Get in touch to discover how we can design a tailored solution that meets your specific needs efficiently, safely, and on time

Our services in the Metals & Minerals field include:

- Health and safety management

- Project control and management

- Site management and supervision

- Heavy equipment offloading and unpacking

- Quality checks and inspections

- Floor marking (manual and laser tracker)

- Material handling and logistics

- Equipment positioning and installation

- Structural steel assembly and erection

- Cooling water system installation

- Media supply pipeline installation

- Grease and lubrication system installation

- Electrical and instrumentation work

- Cable installation and management (40km+ capacity)

- Precision alignment and levelling

- Shimming and anchoring services

- Commissioning support and testing

- Cleaning and decontamination

- Equipment relocation and transport

- Decommissioning and dismantling

- Quality documentation and reporting

- Crane operations and heavy lifting

- Pre-assembly and modular construction

Advanced silicon metal plant installation in extreme Arctic conditions

Beck & Pollitzer completed the installation of one of the world’s most advanced and environmentally-friendly silicon metal production facilities in Iceland. This landmark project demonstrated our capability to deliver complex heavy industrial installations in the most challenging environments.

The challenge: Our client, a global leader in metals and minerals plant technology, required complete mechanical, piping, and electrical installation of an advanced SAF (Submerged Arc Furnace) plant. The team needed to manage 8,000 tons of equipment during two severe Arctic winters with extended polar nights. The project demanded coordination of over 400 international employees rotating between Iceland and their home countries, working alongside 8 different contractors throughout the 20-month timeline.

The Beck & Pollitzer solution: Drawing on over 160 years of engineering expertise, we executed comprehensive project management that prioritised safety and precision. Our team developed specialised protocols for polar night operations, implemented robust logistics systems for equipment handling in extreme conditions, and established clear communication frameworks across all contractors. We provided full commissioning support, including cold function tests of the SAF plant and auxiliary systems.

The outcome: Beck & Pollitzer delivered the complete installation on time with a zero-incident safety record – a testament to our rigorous “Safety First” commitment. The client gained a fully operational, environmentally-friendly production facility ready to meet global silicon metal demand.

If you require expert heavy machinery installation or factory relocation services, our global teams are ready to ensure your success. Contact us today to discuss your requirements with an expert.

300

Operatives on site

8,000

tons of equipment relocated

Complex

Logistics and Health & Safety requirements

Robotics equipment installation in India

Beck & Pollitzer has completed the installation of advanced robotics equipment and utilities for one of India’s leading automotive companies, in Maharashtra, India.

The complex project required the installation and commissioning of more than 200…

Large international logistic project

Beck & Pollitzer France undertook a large international logistic project for a renowned automotive manufacturer. The goal of relocating an entire model Tooling (molds and dies) from Spain to Russia was challenging – our team had to work through …

Replacement of robotised underbody production line

One of the biggest automobile manufacturers trusted us with the replacement of an underbody line including fourteen pieces of robots and ten pieces of robot bases at a welding shop in Czech.

The replacement project included electrical and mechanical…

Installation of underbody lines for an automotive manufacturer

Beck & Pollitzer France completed the installation of the Mild-hybrid (MHEV) project of the underbody lines for a multinational automotive manufacturer.

The main task of this project was to relocate, integrate and install various equipment and m…

Plant relocation for the global automotive part manufacturer

Clarkson Industrial, part of Beck & Pollitzer Group was awarded a challenging and complex project to relocate Tier 1 components production facility from South Carolina to Texas in four phases from 2019-2020. The Global Automotive part manufactur…