Automotive

Automotive industry

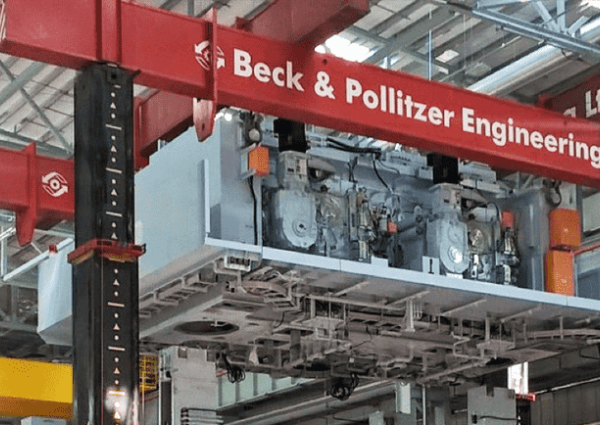

Beck & Pollitzer is your trusted partner for precision machinery moving and installation services tailored to the dynamic Automotive industry, including the rapidly growing Electric Vehicle (EV) sector. With a proven track record of handling complex equipment, from robotic arms to entire assembly lines, we deliver safe, efficient, and reliable solutions that minimise downtime and optimise production.

Beck & Pollitzer offers comprehensive services for your Automotive machinery needs. Our experienced team specialises in the safe and efficient relocation of heavy machinery, ensuring minimal disruption to your operations. We have the expertise to carefully dismantle and reassemble complex equipment, ensuring precision and accuracy.

Our logistics experts coordinate the transportation of your machinery, ensuring safe and timely delivery. We provide professional installation services and meticulous commissioning to ensure your machinery is fully operational.

Expertise in Automotive machinery:

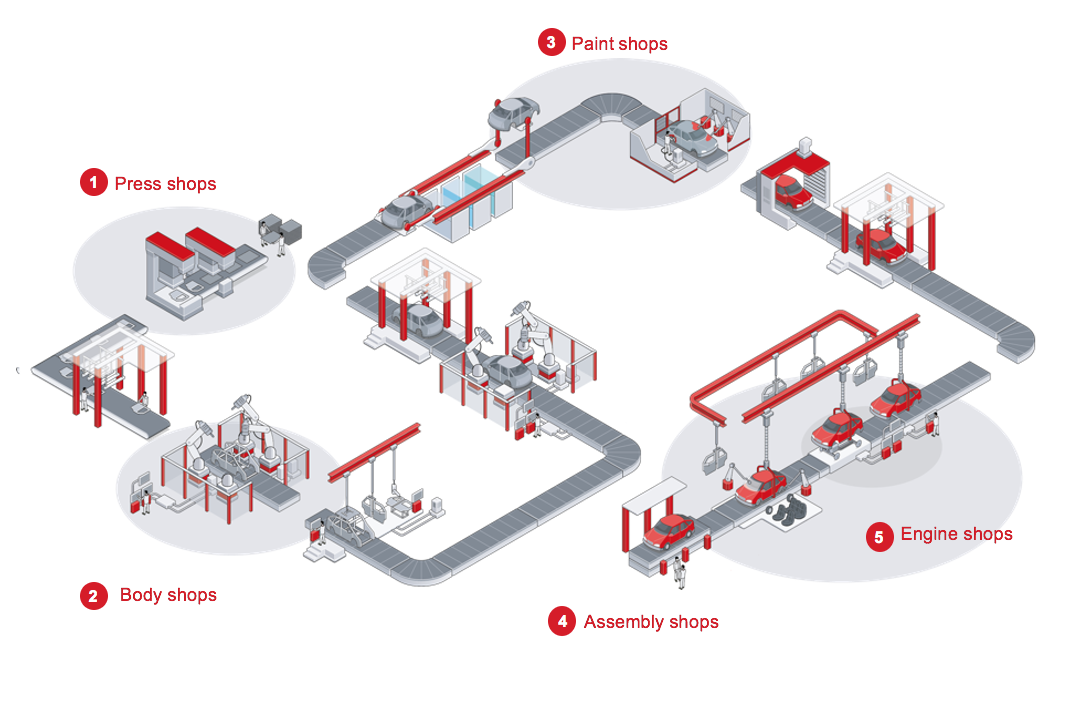

We have deep knowledge in handling a wide range of machinery commonly used in the Automotive industry, including:-

Robotic Arms: For welding, painting, and assembly tasks.

-

CNC Machines: For precision cutting and shaping of metal parts.

-

Presses: For forming metal sheets into car parts.

-

Injection Moulding Machines: For producing plastic components.

-

Conveyor Systems: For transporting parts along the assembly line.

-

Laser Cutting Machines: For precise cutting of various materials.

-

Hydraulic Presses: For forming and shaping metal parts.

-

Engine Testing Machines: For testing engine performance and emissions.

-

3D Printing Machines: For rapid prototyping and manufacturing.

-

Assembly Lines: For body, interior, exterior and final vehicle assembly.

Our clientele

We have built a strong portfolio of clients in the Automotive industry, which includes leading global manufacturers, component suppliers, original equipment manufacturers (OEMs), and Tier 1 and Tier 2 support manufacturers.Why choose Beck & Pollitzer?

Beck & Pollitzer’s team boasts a proven track record in this industry, offering tailored solutions to meet your unique needs. We prioritise safety and efficiency in all our operations, ensuring minimal downtime and a smooth project execution. Our commitment to precision and quality guarantees that your machinery is installed and commissioned to the highest standards.Contact us today to discuss your Automotive machinery moving and installation project. Our team is ready to provide expert guidance and tailored solutions to help you achieve your goals.

Our services in the Automotive field include:

- Project control

- Dedicated project management

- Site management and supervision

- Risk assessments

- Health and safety management

- Electrical integration

- Material management & logistics

- Decommissioning of existing machinery

- Mechanical assembly

- Internal reorganisation

- Storage of equipment

- Metrology and laser tracking

- Alignment and positioning of equipment

- Electrical panel installation

- Control system integration

- Multilingual client liaison

- Electrical testing and validation

- Maintenance support, including decommissioning

- Commissioning and handover support

Automotive industry

Beck & Pollitzer is your trusted partner for precision machinery moving and installation services tailored to the dynamic Automotive industry, including the rapidly growing Electric Vehicle (EV) sector. With a proven track record of handling complex equipment, from robotic arms to entire assembly lines, we deliver safe, efficient, and reliable solutions that minimise downtime and optimise production.

-

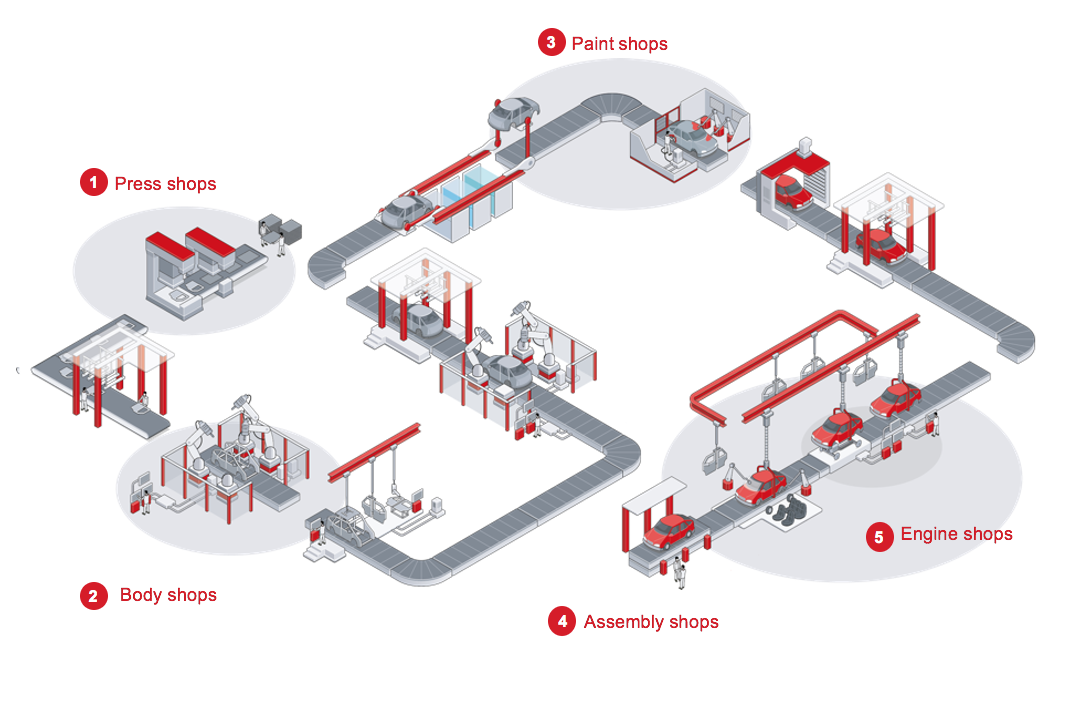

Robotic Arms: For welding, painting, and assembly tasks.

-

CNC Machines: For precision cutting and shaping of metal parts.

-

Presses: For forming metal sheets into car parts.

-

Injection Moulding Machines: For producing plastic components.

-

Conveyor Systems: For transporting parts along the assembly line.

-

Laser Cutting Machines: For precise cutting of various materials.

-

Hydraulic Presses: For forming and shaping metal parts.

-

Engine Testing Machines: For testing engine performance and emissions.

-

3D Printing Machines: For rapid prototyping and manufacturing.

-

Assembly Lines: For body, interior, exterior and final vehicle assembly.

Our clientele

We have built a strong portfolio of clients in the Automotive industry, which includes leading global manufacturers, component suppliers, original equipment manufacturers (OEMs), and Tier 1 and Tier 2 support manufacturers.

Assembly line relocation to Mexico

Beck & Pollitzer completed a 2,500-man-hour project, relocating an assembly line from Hungary to Mexico.

The machinery was designed for assembling the steering components of cars. Our division was responsible for dismantling the equipment in Hungary and reinstalling it in Mexico. This included all the mechanical and electrical works, as well as alignments and levelling.

Our team worked to a strict schedule, which was challenging due to the multiple companies involved in the project. We successfully collaborated with several teams, including the Mexican and Hungarian embassies.

Weather was a further complication; a hurricane rushed through the region, delaying the transport. However, even these extreme circumstances did not stop the team from completing this heavy equipment moving project on time and within budget.

Strict

schedule met

2,500

man hours

10,000

kilometres relocation distance