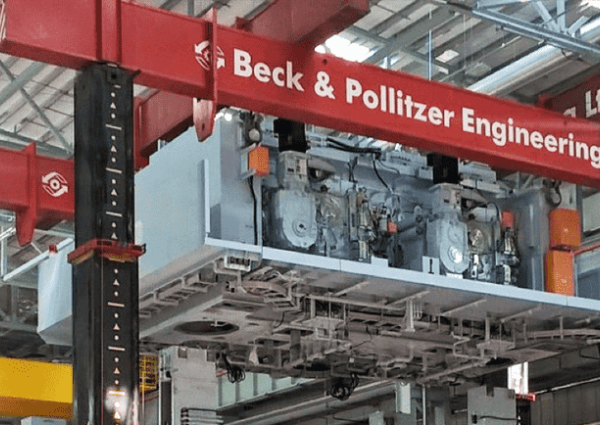

Engineering Services

Engineering services

Beck & Pollitzer can offer a range of engineering services for its clients, such as:

Piping design & installation We have a team of highly skilled mechanical fitters and pipe fitters who can carry out all your pipework or ductwork. This includes design and procurement as well as installation, fitting work and pressure testing.

Electrical design & installation Beck & Pollitzer is an approved NICEIC contractor. By successfully registering with this scheme, we therefore guarantee our electrical work always meets the highest possible standards.

Our electrical engineers are able to carry out a wide range of industrial electrical installations to suit your needs. These include control panel installation, distribution supplies, and the design and installation of all internal wiring, through to final safety checks. We can provide all the necessary design, test data and information, as well as being fully compliant with safety procedures.

We provide our clients with a seamless service by fully integrating our electrical works with our other installation services.

Steelwork design & installation A Beck & Pollitzer speciality is having the ability to design or modify any kind of platform or steelwork to fit your equipment. Our team of steel fabricators and welders can then erect the bespoke product onsite.

Beck & Pollitzer has a broad skill set. Work specification often changes mid-project, but Beck & Pollitzer is always able to adapt thanks to its wide range of services and support equipment.

Beck & Pollitzer Engineering Services:

- Approved contractor for the National Inspection Council for Electrical Installation Contracting (NICEIC)

- Fully integrated service for seamless client interaction

- In-house capability in machine tool support, control systems and maintenance

- In-house specialist welders for bespoke equipment design, manufacture and installation

- Highly skilled mechanical and pipe fitters

- Comprehensive service from initial design work to final checks

- Commitment to Health & Safety

Installation of plant in Iceland

Beck & Pollitzer completed the installation of a new plant in Iceland, following 2 years of negotiations. The project lasted 20 months and involved over 400 employees.

The plant in question is one of the most advanced and environmentally-friendly silicon metal production plants in the world. During its erection, our team was responsible for all of the mechanical, piping and electrical work involved. This included:

-

Offloading 8,000 tons of equipment, plus ducting and pipework during 2 heavy winters and polar nights

-

The installation and erection of new parts

-

Assistance with cold function tests and commissioning of SAF plant and all auxiliary equipment

The three biggest challenges for this project were:

-

The completion of mechanical and electrical works before the deadline

-

The demanding project management and logistics for hundreds of workers, who rotated between the site and their home countries

-

The co-operation between the Beck & Pollitzer team and other contractors on site (amounting to over 500 people in 8 companies)

The project was completed on time, without incident, and – above all – to the client’s satisfaction.

8,000

tons of equipment installed

300

operatives

Complex

logistics and Health & Safety requirements