News

Machinery rigging, Rigging & Rigger Services | Beck & Pollitzer

What is Rigging

Rigging is the process of moving, unloading and loading heavy or bulky goods using specialised equipment. It is the use of such specialised equipment and mechanisms that distinguishes rigging from ordinary loading operations.

Therefore, equipment rigging is a necessity at any industrial company for heavy machinery transport and movement of large-sized tools. The rigging of machines must begin with the preparation of all documents including scope of work, schedules, diagrams, and the use of rigging equipment in compliance with labor protection and safety rules. In addition, the project plans include text and graphic parts with a detailed description of each stage of rigging.

Types of rigging equipment

Beck & Pollitzer has its own warehouse of equipment necessary for carrying out rigging work. Our wide fleet of specialised and advanced rigging equipment makes it possible to find unique and customised solutions for our customers.

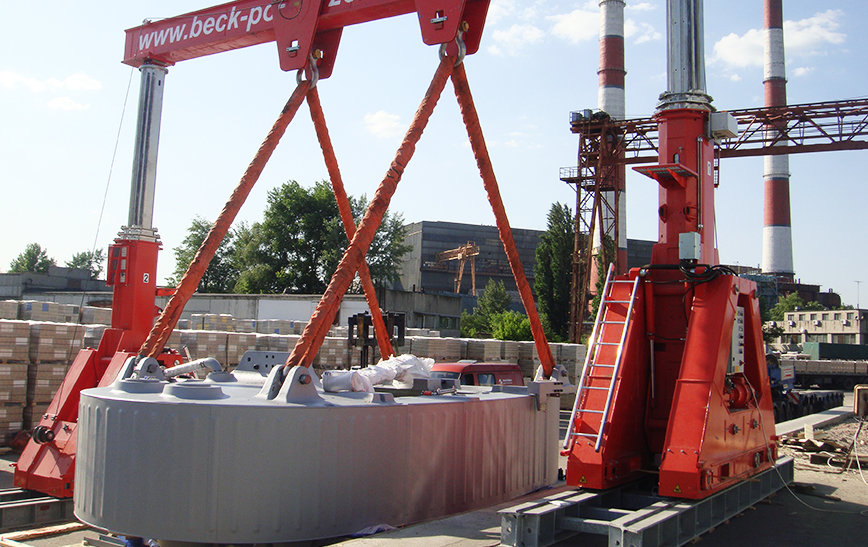

In addition to loaders, Beck & Pollitzer has hydraulic gantry systems for rigging equipment, lifting up to 1,100 tons. Our experienced engineers will be able to specify the relevant portable system based on the weight, dimensions and type of the required operation, and trained riggers will be able to determine the heavy lifting requirements of even the largest equipment.

Therefore, when choosing a rigging company, you need to make sure that it has experience of using a wide variety of rigging equipment and is able to offer the best solution.

Riggers – what do riggers do

A rigger is a professional who specialises in securely lifting, moving and positioning heavy loads with the help of rigging equipment. A rigger must know the technology and the rules for using rigging mechanisms and devices. The main duties of a rigger include preparing the materials before loading, attaching the heavy loads to structures or cranes, inspecting rigging before final use, operating heavy machinery, dismantling and post-rigging inspections.

In addition, loaders and riggers must be aware of methods of temporary decking construction, rules of equipment disassembling and ensure compliance with health and safety regulations. An additional advantage would be if the rigger knows the basics of plumbing and carpentry. At Beck & Pollitzer, all our riggers and heavy equipment movers are trained, certificated and are on a continuous program of refresher training.

Why use a specialised rigging company

Equipment rigging is one of the most complex and technical types of work. When using a specialized rigging company like Beck & Pollitzer, the customer will be able to mitigate two risks in production: the risk of damaging the equipment and the risks associated with labour safety. To prevent the occurrence of emergency and life-threatening situations for employees, trained and experienced Beck & Pollitzer riggers strictly comply with all health and safety rules and regulations. Working without specialized tools and equipment not only enables the equipment at risk of falling and damage, but also risks the health and safety of personnel.

Rigging Safety

Before starting a rigging project, it is necessary to consider the safety of the chosen method of rigging, based on the following factors:

- topographic – terrain and planning features

- meteorological – especially if the rigging takes place in open areas

- ergonomic – illumination of the workplace and other factors affecting the performance of employees, which can lead to additional stress and, as a result, errors

- the ability to monitor the movement of cargo

- potential hazards

Other rigging safety measures include:

- Rigging must take place in strict accordance with the previously developed project. When developing and performing rigging of machine equipment, it is necessary to provide for maximum mechanisation, automation, and remote work. If possible, manual operations should be eliminated or reduced to a minimum.

- The communication system between all participants in the process should be selected considering specific factors and ensure the clarity and speed of data transmission.

- During the rigging process, all parts must be securely fastened, and suitable measures must be taken to ensure the stability of the load. Thus, it is necessary to completely exclude the possibility of uncontrolled movement of the equipment or its parts.

- It is also necessary to check that the lifting mechanisms are not overloaded, considering the total weight of the load and the height to which it is necessary to lift. Slinging of the load must be carried out in accordance with the slinging scheme by a specialist slinger.

- Before rigging, the load must be raised by 200-300 mm and held in this position for at least 10 minutes, after which the reliability of the load strapping is checked one more time. If any mechanism or unit malfunctions, rigging must be stopped immediately, and employees must leave the danger zone until the problem is eliminated.

- All these rules will allow the equipment to be rigged as safely as possible for all personals involved in the process.

Rigging Price

To calculate the cost of rigging in compliance with all the nuances, a Beck & Pollitzer specialist would visit the rigging site to write a full report, including measurements, proposed technology and rigging equipment. Based on this report, the company will be able to offer the safest and most convenient plan to carry out the rigging and with a detailed price list.

If it is not possible to visit the site, the calculation can be made on the basis of the technical requirements from the customer, including type of cargo, drawings and description, distance and features of transportation, as well as the layout of the premises and other conditions necessary to determine the cost of rigging.

Our 150 years of experience and expertise in industrial services including rigging, machinery installation and factory relocation will guarantee high quality services and customer satisfaction. To discuss all your rigging needs please contact our local office for further advice and assistance.